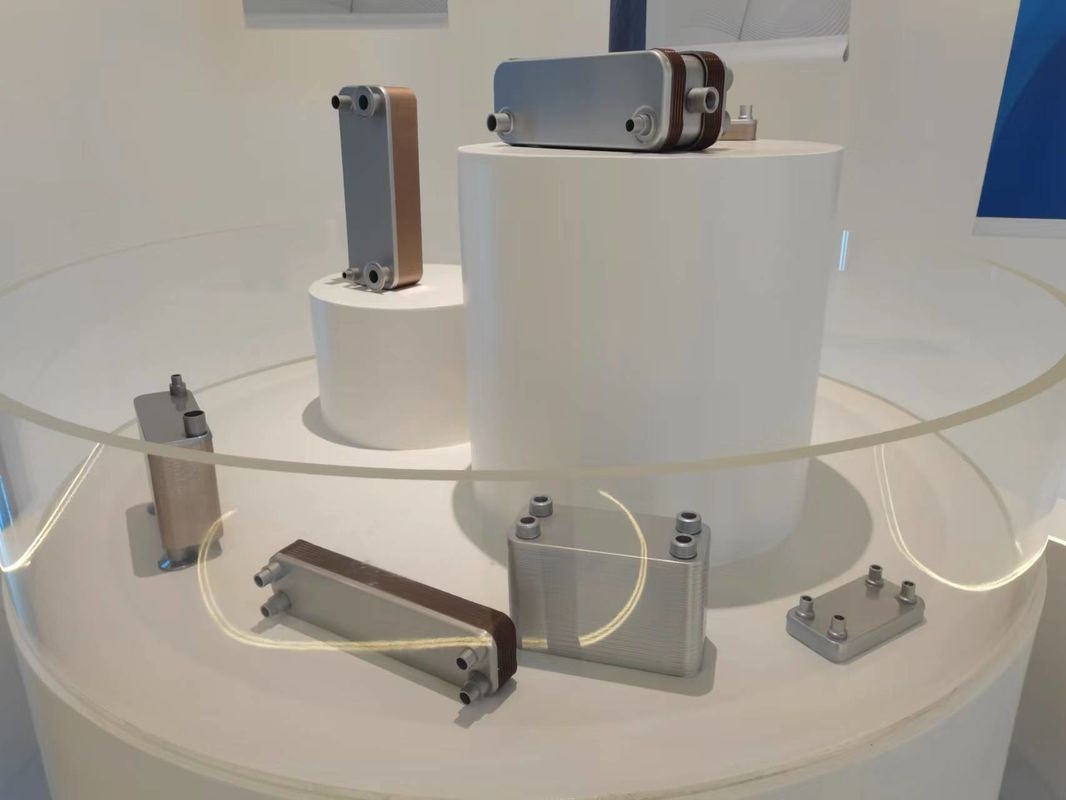

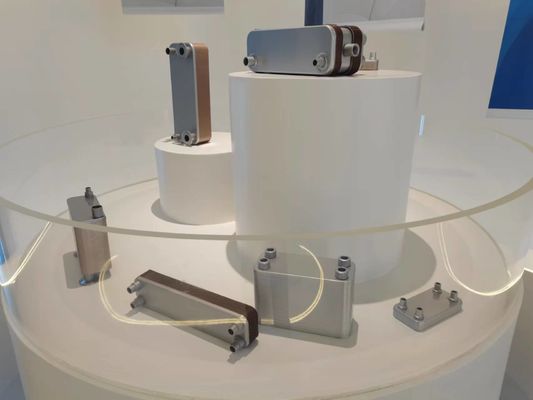

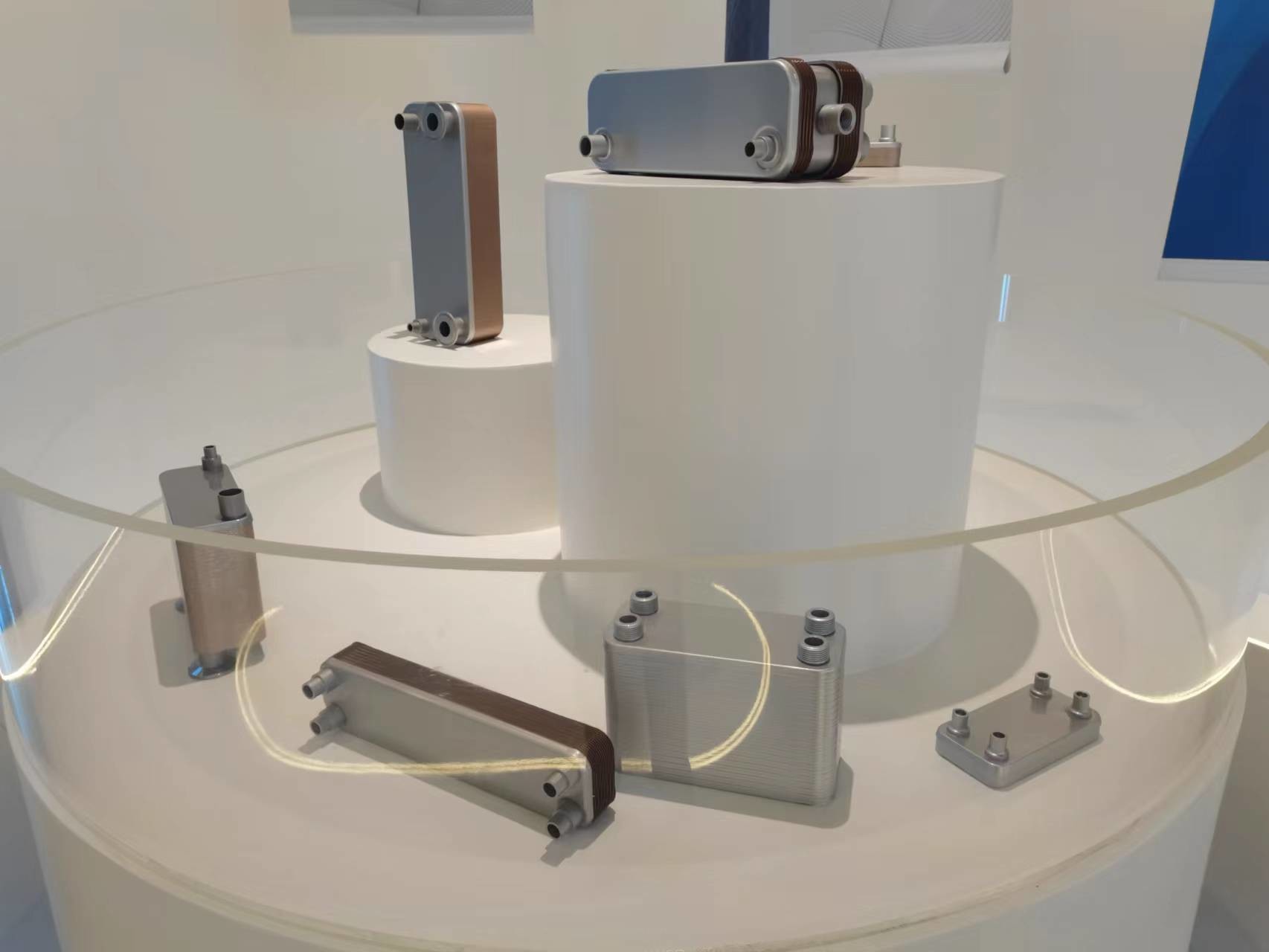

Innovative Solution Copper Brazed Plate Heat Exchanger For Refrigeration Systems Description:

Copper Plate Heat Exchanger

Copper Plate Heat Exchanger is a kind of heat exchange equipment made of copper material, which is widely used in chillers, heat pumps and other refrigeration systems. It has a maximum temperature of 225℃ and a maximum pressure of 4.5Mpa, with various connection types such as SAE Flanged, Flanged, Male Thread, Female Thread, Soldering, etc. It also has a design pressure of up to 4.5Mpa. It is a reliable and efficient heat exchanger for chiller, heat pump and other refrigeration applications.

This chiller plate heat exchanger is made of high-quality copper which is extremely durable and provides excellent heat transfer performance. It has a compact design that allows for easy installation and operation. Its features include high thermal efficiency, low pressure drop and a long service life. It is perfect for chillers, heat pumps and other refrigeration systems.

The copper plate heat exchanger is an ideal solution for chiller and heat pump applications. It provides high performance, reliability and efficiency. It is easy to install and maintain and provides maximum heat transfer performance with minimal pressure drop. This makes it the perfect choice for chillers, heat pumps and other refrigeration systems.

Features:

- Product Name: Copper Plate Heat Exchanger

- Max Temperature: 225℃

- Connection Type: SAE Flanged, Flanged, Male Thread, Female Thread, Soldering

- Design Pressure: Max 4.5Mpa

- Design Temperature: -196℃→ 225℃

- HS CODE: 8419500090

- Water to Water Plate Heat Exchanger

Technical Parameters:

| Parameter |

Value |

| Size |

Customizable |

| Connection Type |

SAE Flanged, Flanged, Male Thread, Female Thread, Soldering |

| Type |

Plate Heat Exchanger |

| Design Pressure |

Max 4.5Mpa |

| Max Temperature |

225℃ |

| Max Pressure |

4.5Mpa |

| Material |

Copper |

| Warranty |

One Year |

| Design Temperature |

-196℃→ 225℃ |

| Flow Rate |

8→300m³/h |

| Application |

Water to Water Plate Heat Exchanger, Refrigeration Plate Heat Exchanger |

| TYPE |

B(mm |

C(mm |

D(mm) |

E(mm) |

Thickness

(mm)

|

Weight(Kg) |

Max Flow (m3/h) |

Design Pressure (Mpa) |

| SB14 |

77 |

42 |

206 |

172 |

9+2.3N |

0.7+0.06N |

8 |

1/3/4.5 |

| SB16 |

78 |

42 |

208 |

172 |

9+2.24N |

0.6+0.049N |

8 |

1/3/4.5 |

| SB18 |

95 |

50 |

210 |

165 |

7+3.1N |

0.7+0.06N |

8 |

1 |

| SB20B |

78 |

42 |

318 |

282 |

9+2.3N |

1+0.08N |

8 |

3/4.5 |

| SB20C |

77 |

42 |

313 |

278 |

10+1.28N |

0.9+0.07N |

8 |

3/4.5 |

| SB26 |

111 |

50 |

310 |

250 |

10+2.32N |

1.3+0.12N |

18 |

3/4.5 |

| SB26F |

107 |

50 |

307 |

250 |

10+1.98N |

1.3+0.1N |

18 |

3/4.5 |

| SB28B |

120 |

72 |

290 |

243 |

10+2.36N |

1.5+0.133N |

18 |

3/4.5 |

| SB28C |

120 |

63 |

290 |

234 |

10+2.36N |

1.5+0.133N |

18 |

3/4.5 |

| SB30 |

126 |

70 |

307 |

250 |

10+2.35N |

2.2+0.16N |

18 |

3/4.5 |

| SB52A |

111 |

50 |

526 |

466 |

9+2.32N |

2.6+0.21N |

18 |

3/4.5 |

| SB52B |

111 |

50 |

526 |

466 |

9+2.32N |

2.6+0.19N |

18 |

3/4.5 |

| SB53 |

106 |

50 |

522 |

466 |

9+2.1N |

2.6+0.27N |

18 |

3/4.5 |

| SB62A |

120 |

63 |

528 |

470 |

10+2.35N |

2.379+0.194N |

18 |

3/4.5 |

| SB62B |

120 |

63 |

528 |

470 |

10+2.35N |

2.379+0.194N |

18 |

3/4.5 |

| SB65 |

125 |

65 |

540 |

480 |

11+2.28N |

2.5+0.228N |

18 |

3/4.5 |

| SB95A |

189 |

92 |

616 |

519 |

11+2.7N |

7.8+0.44N |

42 |

3/4.5 |

| SB95B |

189 |

92 |

616 |

519 |

11+2.7N |

7.8+0.44N |

42 |

3/4.5 |

| SB120A |

246 |

174 |

528 |

456 |

10+2.34N |

7.2+0.52N |

42 |

3/4.5 |

| SB120B |

246 |

174 |

528 |

456 |

10+2.34N |

7.2+0.52N |

42 |

3/4.5 |

| SB190 |

303 |

179 |

695 |

567 |

13+2.3N |

12+0.61N |

100 |

1.6/2.1/3 |

| SB200A |

320 |

188 |

742 |

603 |

14+2.7N |

13+0.67N |

100 |

1.5/2.1/3 |

| SB200B |

320 |

188 |

742 |

603 |

14+2.7N |

13+0.67N |

100 |

1.5/2.1/3 |

| SB200E |

320 |

207 |

742 |

624 |

14+2.7N |

13+0.67N |

100 |

1.5/2.1/3 |

| SB202 |

319 |

188 |

741 |

603 |

16+2.85N |

13+0.957N |

100 |

2.1/3 |

| SB300 |

370 |

118(95.5) |

995 |

861(816) |

17+2.675N |

20+1.26N |

200 |

1.6/2.1/3 |

| SB500 |

304 |

179 |

982 |

854 |

17+2.29N |

26.6+0.93N |

200 |

2.1/3 |

| SB01 |

390 |

204 |

1320 |

1132 |

22+2.75N |

30+1.8N |

300 |

3/4.5 |

Applications:

Tenkai copper brazed plate heat exchangers are ideal for a wide range of industrial and commercial applications, such as refrigeration, heating, and other applications. The Tenkai plate heat exchangers are manufactured in China and certified by ISO to guarantee quality and performance. They come with a minimum order quantity of 1 wooden package, and at a competitive price. Packaging details include wooden package, and delivery time is within five working days. Payment terms are T/T, L/C, D/P, and the supply ability is 8000 Pieces/Month. This heat exchanger is designed to operate at temperatures up to 225℃, and features connection types such as SAE Flanged, Flanged, Male Thread, Female Thread, Soldering. Tenkai also provides a one year warranty for this product, and the HS CODE is 8419500090. The flow rate is 8→300m³/h.

Customization:

Copper Plate Heat Exchanger - Customized Service

Brand Name: Tenkai

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1 wooden package

Price: Competitive

Packaging Details: Wooden Package

Delivery Time: Within five working days

Payment Terms: T/T, L/C, D/P

Supply Ability: 3600 Pieces/Month

Material: Copper

Design Pressure: Max 4.5Mpa

Flow Rate: 8→300m³/h

HS CODE: 8419500090

Warranty: One Year

Chiller Plate Heat Exchanger is one of our signature products and is widely used in various industries. Our Chiller Plate Heat Exchanger is made of top-grade copper and is designed with maximum pressure of 4.5Mpa and flow rate of 8→300m³/h. It is certified with ISO and comes with one year warranty. The minimum order is one wooden package and delivery time is within five working days. Competitive price and reliable supply ability of 8000 pieces/month are both available. Please contact us to get more details.

Support and Services:

Copper Plate Heat Exchanger Technical Support and Services

We offer a full range of technical support and services tailored to the specific needs of our customers. Our experienced team of professionals is available to respond to customer inquiries and provide guidance on product selection, installation and maintenance. We are committed to helping our customers maximize the performance and lifespan of their Copper Plate Heat Exchanger.

Technical Support

Our technical support team is on hand to provide expert advice on all aspects of Copper Plate Heat Exchanger. We can assist with product selection, installation, maintenance, troubleshooting, and more. Our team is available to answer questions and provide advice in order to ensure that customers get the most out of their Copper Plate Heat Exchanger.

Maintenance and Repair Services

We provide comprehensive maintenance and repair services to ensure that your Copper Plate Heat Exchanger is operating at optimal performance. Our team can inspect and diagnose any issues and provide a solution to restore your Copper Plate Heat Exchanger to peak performance. We can also provide advice on how to maintain and extend the lifespan of your Copper Plate Heat Exchanger.

Customer Training

Our team can provide training to ensure that your staff is knowledgeable and proficient in the use of Copper Plate Heat Exchanger. We offer a range of training packages that can be tailored to meet the specific needs of your business. Our training packages can include basic operation, troubleshooting, and maintenance, as well as more in-depth instruction. Our goal is to ensure that your staff has the knowledge and skills necessary to successfully operate and maintain your Copper Plate Heat Exchanger.

Packing and Shipping:

The Copper Plate Heat Exchanger is packaged and shipped according to the following guidelines:

- The Copper Plate Heat Exchanger should be securely wrapped in bubble wrap and placed in a cardboard box.

- The box should be properly sealed with tape to ensure the item is secure.

- The box should be labeled with the recipient’s address and the description of the contents.

- The Copper Plate Heat Exchanger should be shipped via a reliable delivery service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!