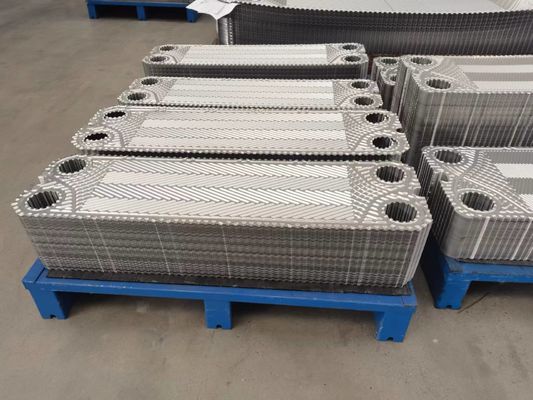

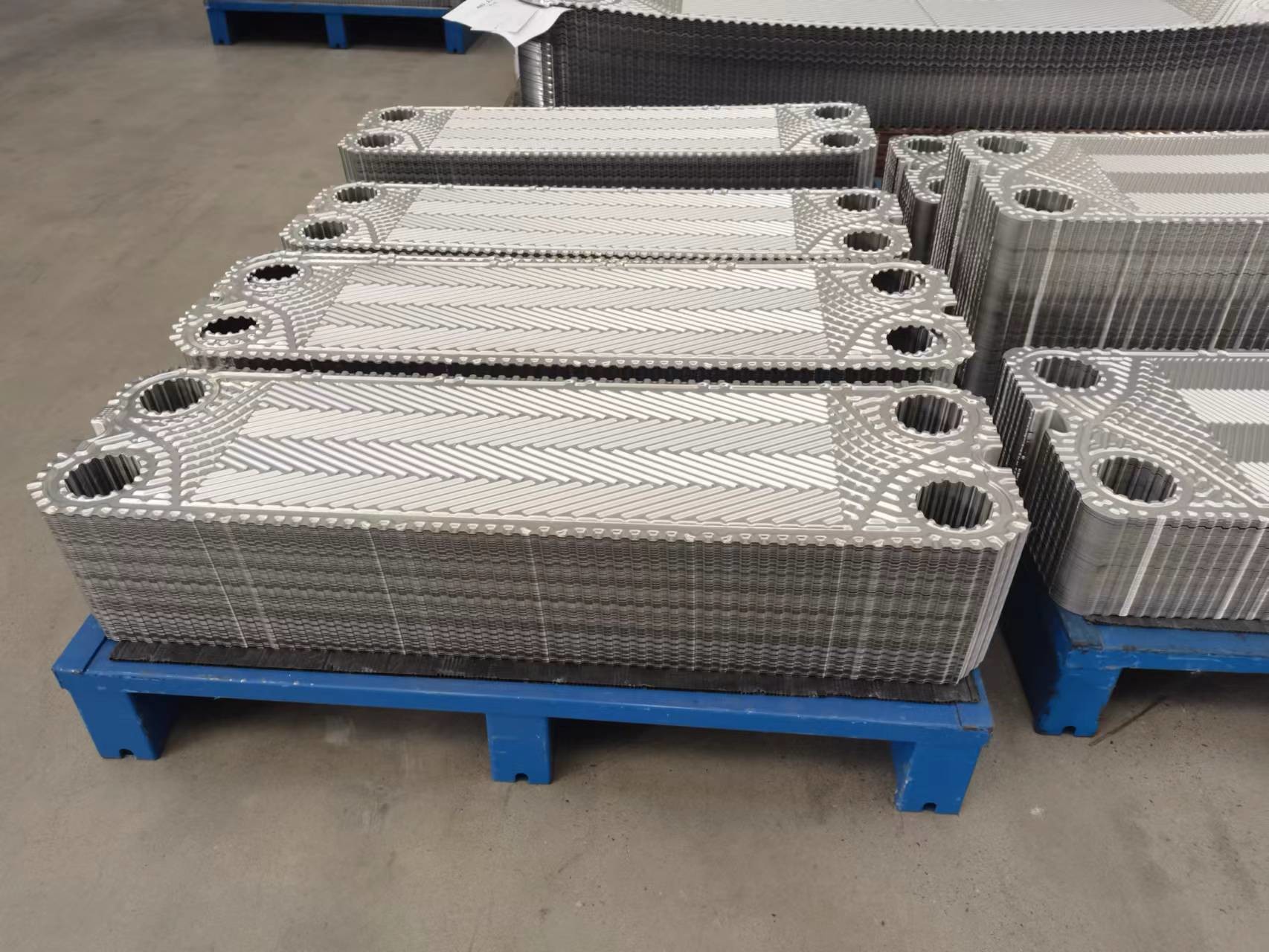

Box Material Q35 Stainless Steel Inside Plate Heat Exchanger For Potable Water Applications And Industrial Processes

| TYPE |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

THICKNESS(mm) |

WEIGHT(Kg) |

MAX FLOW m3/h) |

DESIGN PRESSURE (Mpa) |

| BT350BR |

318 |

160 |

1060 |

912 |

44+2.23N |

79.3+1.31N(N<132)

82.23+1.404N(N≥132)

|

50 |

0.5 |

|

|

|

Application:

The box-type fusion-welded plate heat exchanger finds application in a wide range of industries and processes that require efficient heat

transfer. Some common applications include:

Oil and gas industry: Used for heat recovery, oil cooling, and gas processing in upstream, midstream, and downstream operations.

Chemical processing: Employed in chemical reactors, distillation columns, and heat recovery systems for efficient heat transfer between process fluids.

Power generation: Used in power plants for heat exchange between different fluids, such as cooling water, steam, and flue gases.

Refrigeration and HVAC systems: Utilized for heat exchange between refrigerants and cooling water in chillers, air conditioning units, and refrigeration systems.

Food and beverage industry: Used for pasteurization, sterilization, and temperature control in food processing, brewing, dairy production, and other applications.

Pharmaceutical industry: Employed in the production of medicines, vaccines, and other pharmaceutical products, ensuring precise temperature control during various manufacturing processes.

Petrochemical industry: Used for heat exchange in refining processes, such as crude oil distillation, catalytic cracking, and hydroprocessing.

Marine and offshore applications: Utilized in shipbuilding, offshore platforms, and marine cooling systems for efficient heat transfer in challenging environments.

Petrochemical industry: Used for heat exchange in refining processes, such as crude oil distillation, catalytic cracking, and hydroprocessing.

Marine and offshore applications: Utilized in shipbuilding, offshore platforms, and marine cooling systems for efficient heat transfer in challenging environments.

Advantage :

◆High-pressure capability

Box-type fusion-welded plate heat exchangers are designed to handle high-pressure applications. They can effectively accommodate the demands of industrial processes that require heat transfer under elevated pressures.

◆High heat transfer coefficient

Due to the complex and tortuous nature of the plate channels, the fluid continuously changes its direction, velocity, and generates strong turbulence, resulting in a very low liquid film thermal resistance and achieving high heat transfer coefficients. It is more advanced compared

to shell and tube heat exchangers.

◆compact structure

The plate heat exchanger has a channel gap of only 3-5mm, plate thickness ranging from 0.6-0.8mm, requiring minimal maintenance space. Compared to shell and tube heat exchangers, it occupies only 1/5 to 1/100 of the footprint

◆Easy to clean and test

To remove and clean the plates or replace damaged plates and gaskets, simply loosen and remove the tightening bolts.

◆Easy to increase or decrease heat transfer area

To increase or decrease the heat transfer area, simply add or remove the number of plates.

◆A variety of media heat transfer is possible

In a heat exchanger, if multiple media need to be heat exchanged, it can be achieved by installing intermediate partitions. For example, if three media need to be exchanged, the installation of intermediate partitions can facilitate this process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!