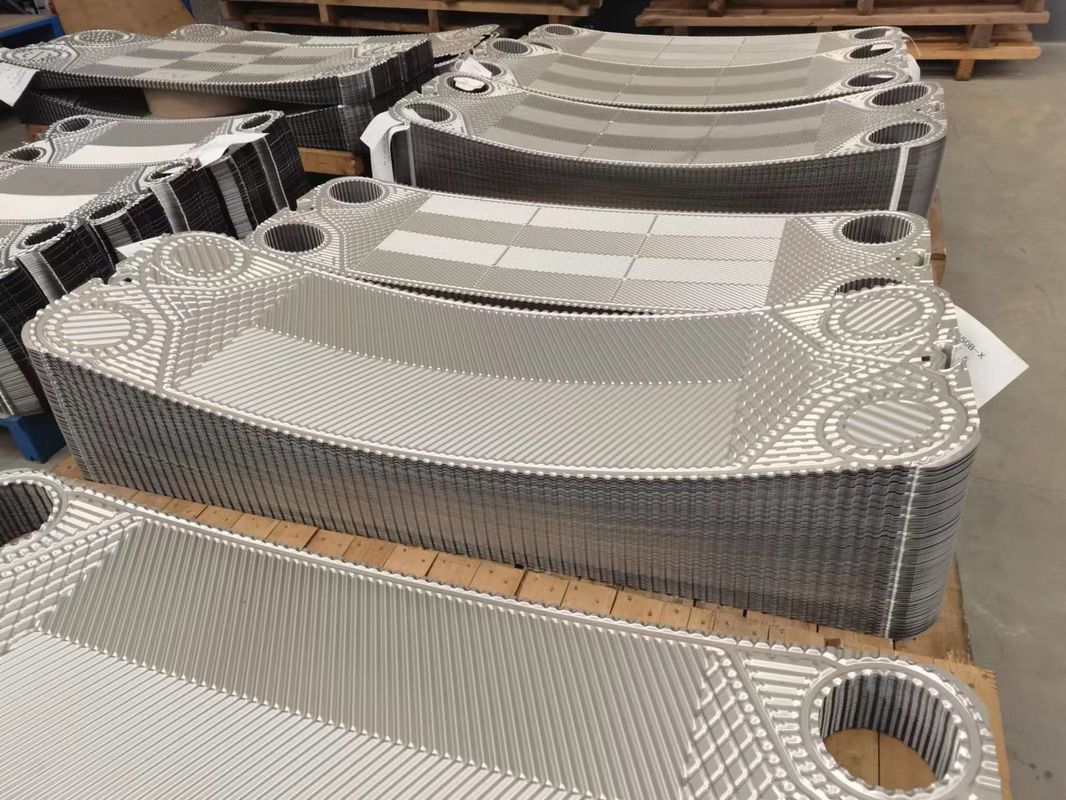

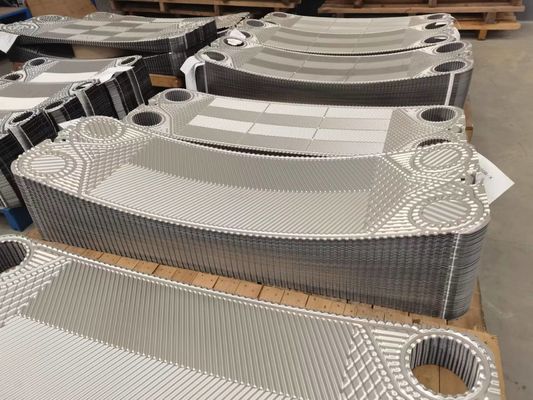

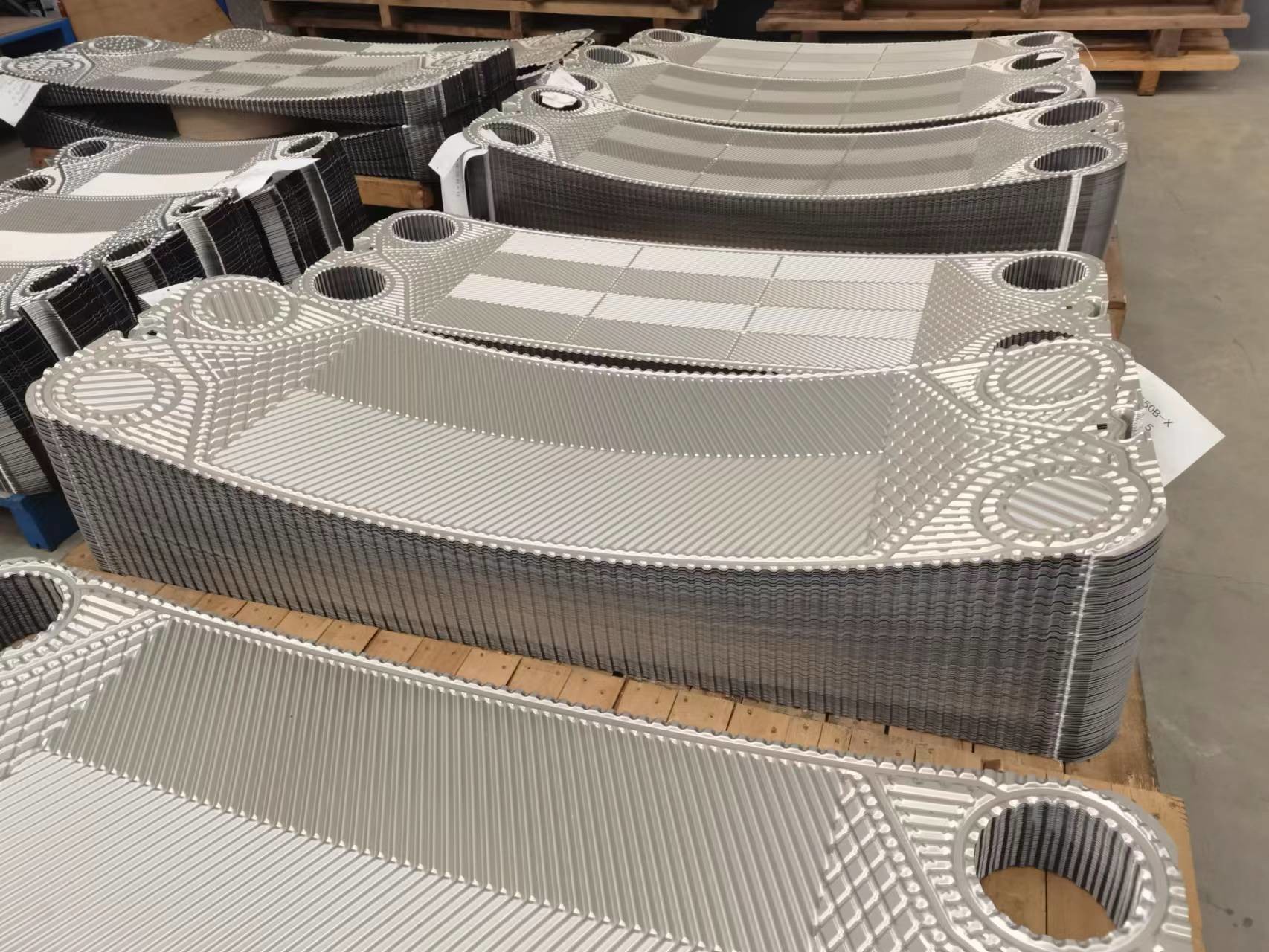

Marine And Engine Cooling And Preheating Systems Stainless Steel Plate Heat Exchanger Multi-Stage Design

| TYPE |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

THICKNESS(mm) |

WEIGHT(Kg) |

MAX FLOW m3/h) |

DESIGN PRESSURE (Mpa) |

| BT350BR |

318 |

160 |

1060 |

912 |

44+2.23N |

79.3+1.31N(N<132)

82.23+1.404N(N≥132)

|

50 |

0.5 |

|

|

|

Steel Industry

Cooling of Quenching Oil

Cooling of Electroplating Solution

Cooling of Gear Lubricating Oil

Cooling of Rolling Mill

Cooling of Wire Drawing Machine Coolant

Other Main Application Area :

Residential heating areas

Mechanical cooling applications

Power plant cooling systems

Cooling systems for piston and turbine operations

Marine and engine cooling and preheating systems

Cooling and heat recovery systems in the sugar industry

Cooling and heat recovery systems in food oil processing

Cooling systems in the chemical industry

Cooling systems in the pharmaceutical industry

Cooling and heating systems in surface treatment

Cooling systems in the paper industry

Cooling and heating systems in the textile industry

Cooling systems in the steel industry

Cooling systems in the automotive industry

Feature :

1, Leak Protection

The safety technology of stainless steel plate heat exchanger is a double-wall plate system designed to allow the detection of any leaks, whether on the outside of the heat exchanger. This safety measure ensures that faulty components can be quickly identified and repaired. As all leaks are external and not internal, the media is always kept separated. This makes the double-wall sanitary plate heat exchanger an ideal solution when working with media that should not be contaminated at any cost.

2,Multi-stage design

Our sanitary plate heat exchanger can also be implemented as a multi-stage solution, where multiple heat exchangers are combined into a single installation, separated by intermediate partitions.

3,High standard and easy maintenance

Our heat exchanger solution complies with stringent industry hygiene requirements and adheres to FDA material standards. The plate pressing process ensures high product quality. We ensure the implementation of flow control, temperature configuration, and appropriate residence time for all media during the processing. The design facilitates quick and trouble-free inspection, maintenance, or cleaning, including Clean-in-Place (CIP), with the convenience of a stainless steel or full stainless steel frame.

4,Save energy

Stainless steel plate heat exchangers can significantly reduce energy consumption and recover up to 95% of energy

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!