Heat Transfer Efficiency Ultra High Pressure Brazed Plate Heat Exchanger

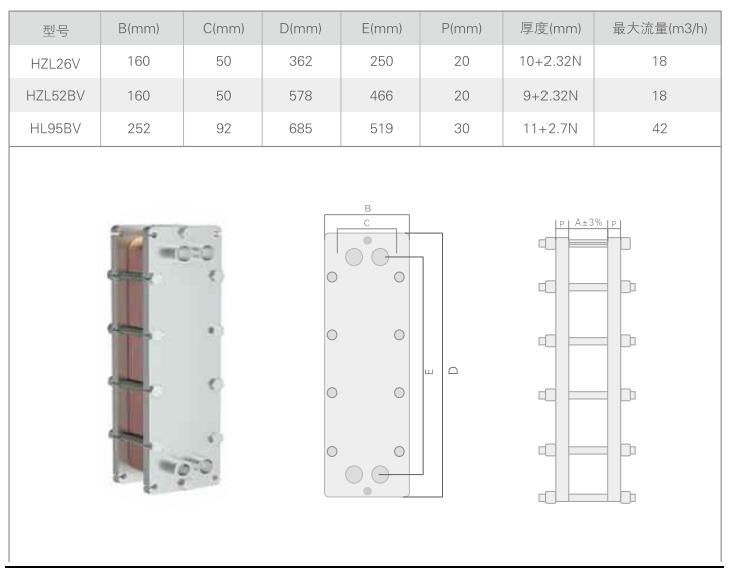

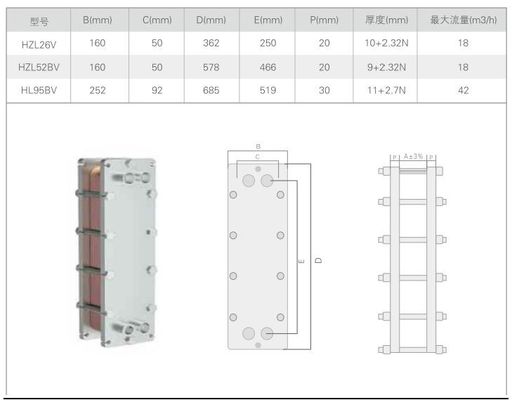

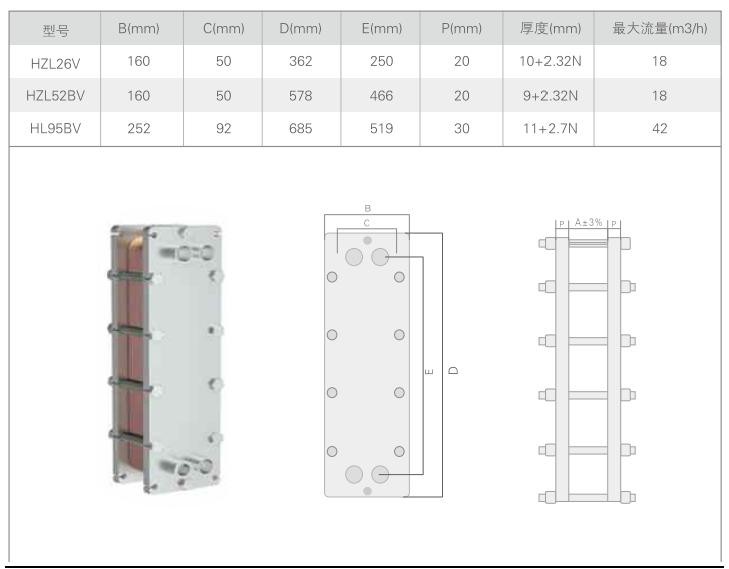

| TYPE |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

THICKNESS(mm) |

P ( mm ) |

MAX FLOW (m3/h) |

| UHP26V |

160 |

50 |

362 |

250 |

10+2.32N |

20

|

18 |

Introduction :

ULTRA HIGH PRESSURE BRAZED Plate Heat Exchanger adopt double splint design , make its compact structure and more pressure-bearing . It can use in heat pump system with R722(CO₂) refrigerating fluid .

A high-pressure plate heat exchanger is a type of heat exchanger specifically designed to operate under high-pressure conditions. It is capable of handling fluids at elevated pressures while efficiently transferring heat between them.

Features and Characteristics :

Robust Construction: High-pressure plate heat exchangers are constructed using materials that can withstand the high pressures involved. Typically, they are made of robust metals such as stainless steel or nickel alloys that offer excellent strength and corrosion resistance.

Plate Design: The plates in high-pressure plate heat exchangers are designed to handle high-pressure differentials. They are often thicker and have reinforced structures to maintain integrity under high-pressure conditions.

Sealing Technology: To ensure reliable operation at high pressures, high-pressure plate heat exchangers employ advanced sealing technologies. Gaskets or seals are carefully selected and designed to provide a tight and durable seal between the plates, preventing any leakage.

Pressure Rating: High-pressure plate heat exchangers are specifically rated to handle elevated pressures. The pressure rating indicates the maximum pressure that the heat exchanger can safely withstand without compromising its integrity.

Heat Transfer Efficiency: Despite the high-pressure operation, these heat exchangers maintain efficient heat transfer performance. The plates in high-pressure plate heat exchangers are designed with optimized patterns and corrugations to enhance heat transfer between the fluids.

Versatility: High-pressure plate heat exchangers find applications in various industries and processes that involve high-pressure fluids. They are commonly used in oil and gas, chemical processing, power generation, and other industrial applications where high-pressure heat exchange is required.

Compact Design: High-pressure plate heat exchangers offer a compact footprint, allowing for efficient use of space. The plates are stacked closely together, providing a large heat transfer surface area within a relatively small volume.

Maintenance and Serviceability: High-pressure plate heat exchangers are designed for easy maintenance. Individual plates can be accessed and replaced if needed, minimizing downtime and reducing maintenance costs.

Applicable temperature : 200 ℃

Design Pressure : 14 Mpa

Test Pressure : 21 Mpa

Remark : splint material is Q235 , bolt for M16 , M20 , and available for suited lifting lug , footing , etc .

Workshop :

Wooden Package :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!