225.C Male Thread Thread SAE Flange Solder Brazed Heat Exchanger For Flow Rate Applications

Product Description:

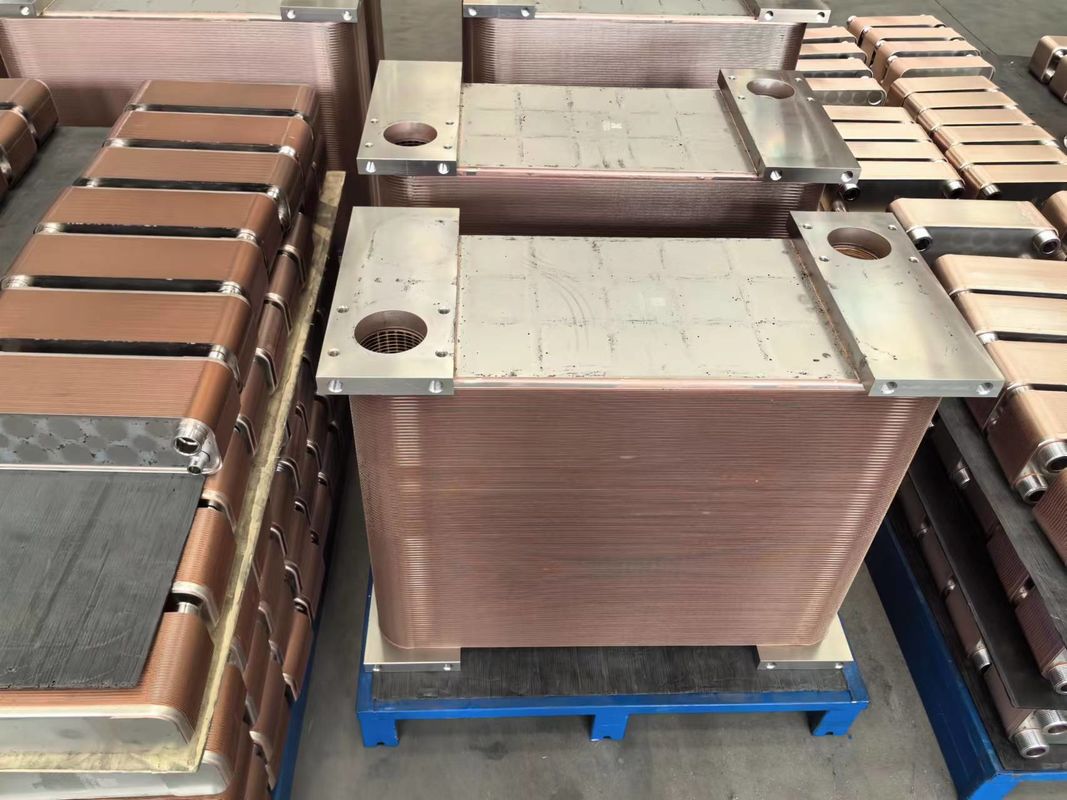

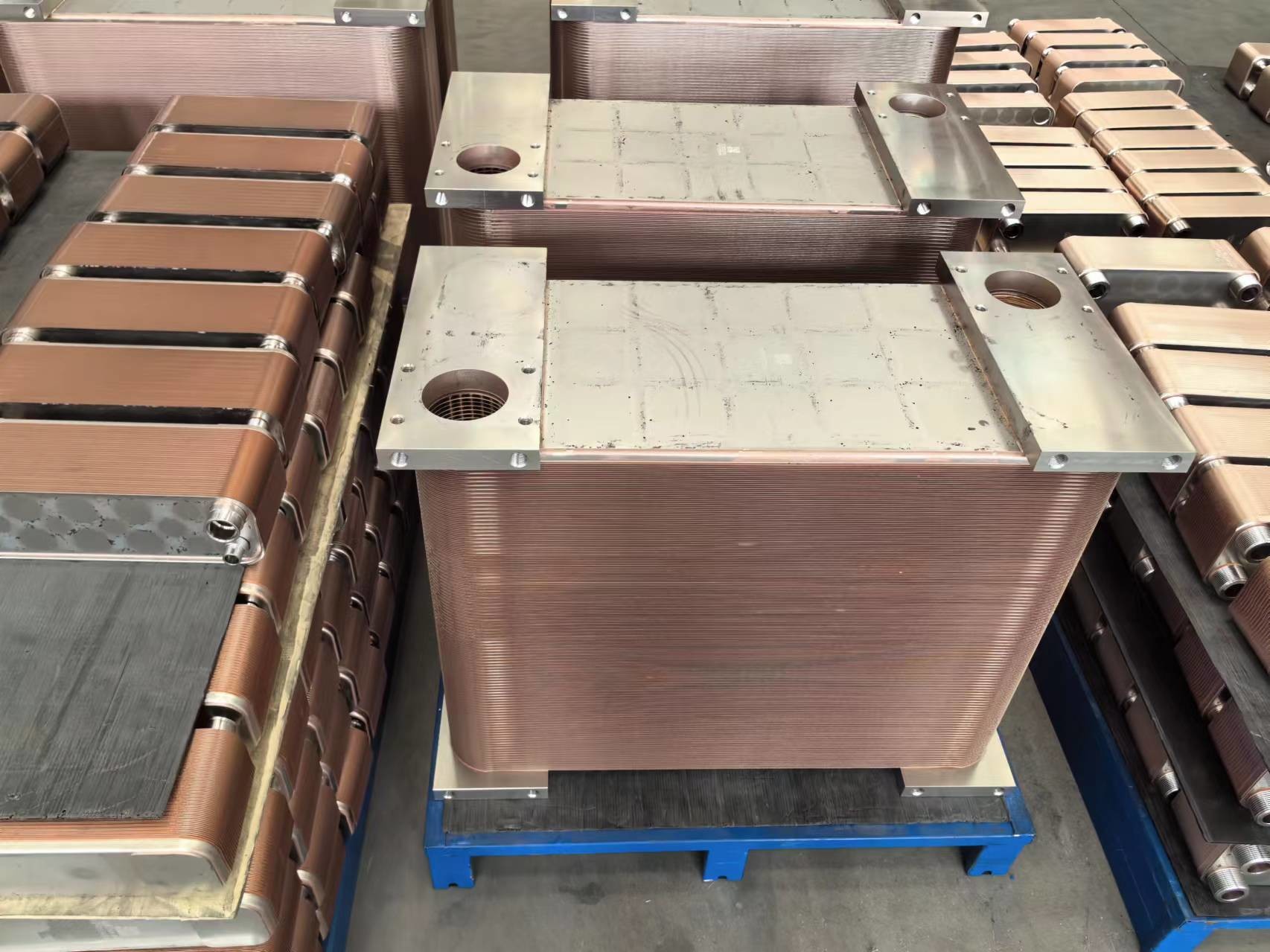

The plate design of this heat exchanger features a chevron pattern, which maximizes heat transfer efficiency. The chevron pattern creates a turbulent flow that enhances heat transfer between the two fluids passing through the exchanger. This design ensures that the Brazed Plate Heat Exchanger delivers efficient heat transfer performance, making it an ideal choice for several applications.

The Brazed Plate Heat Exchanger is built to withstand high pressures, with a maximum pressure of 4.5Mpa. The design temperature range is from -196 to 225 C, which makes it suitable for use in extreme temperature applications. The heat exchanger is also designed to be customized to meet the specific needs of a customer's application.

One of the key benefits of the Brazed Plate Heat Exchanger is that it is compact, making it an excellent choice for applications where space is limited. The compact design also makes it easy to install, maintain, and clean. This heat exchanger is an excellent option for use in various industries such as HVAC, refrigeration, chemical processing, and more.

The Brazed Plate Heat Exchanger is an excellent alternative to other types of heat exchangers such as the Evaporator Plate Heat Exchanger, Full Welded Plate Heat Exchanger, and Fusion Bonded Plate Heat Exchanger. It delivers higher thermal efficiency than the Evaporator Plate Heat Exchanger, while its compact size provides a significant advantage over the Full Welded Plate Heat Exchanger. Additionally, the Brazed Plate Heat Exchanger is more cost-effective than the Fusion Bonded Plate Heat Exchanger while delivering superior heat transfer performance.

Applications:

The Brazed Plate Heat Exchanger is a compact and efficient heat exchanger that is suitable for a wide range of applications. The product has a maximum pressure of 4.5Mpa, and the specifications can be customized to meet specific requirements. The Brazed Plate Heat Exchanger comes with a Chevron plate design that ensures maximum heat transfer between the two fluids.

The Copper Brazed Plate Heat Exchanger is designed for use in applications where high efficiency and compact size are required. The product is suitable for use in the food and beverage industry, HVAC, oil and gas, and refrigeration. The Brazed Plate Heat Exchanger is capable of handling high-pressure and high-temperature applications.

The Fusion Bonded Plate Heat Exchanger is another product from Tenkai that is designed for applications that require a high level of efficiency and reliability. The product is suitable for use in the chemical, pharmaceutical, and petrochemical industries. The Fusion Bonded Plate Heat Exchanger is capable of handling aggressive media and high-temperature applications.

The Evaporator Plate Heat Exchanger is designed for use in applications that require the efficient transfer of heat from one fluid to another. The product is suitable for use in the refrigeration industry, where it can be used to cool liquids and gases. The Evaporator Plate Heat Exchanger is capable of handling low-temperature applications and is highly efficient.

The Brazed Plate Heat Exchanger comes with various connections, including Male Thread, Thread, SAE Flange, and Soldering. The product is highly customizable, and the plate design can be changed to meet specific requirements.

Support and Services:

The Brazed Plate Heat Exchanger is a highly efficient and compact heat transfer solution, suitable for a wide range of applications. Our product technical support and services include:

- Expert technical advice for selecting the right heat exchanger for your application

- Installation and commissioning support

- Regular maintenance and cleaning guidelines

- Repairs and replacement parts

- Training for operation and maintenance

Our team of experienced engineers and technicians are committed to providing the highest level of support and service to ensure optimal performance and longevity of your Brazed Plate Heat Exchanger.

Packing and Shipping:

Product Packaging:

- The brazed plate heat exchanger will be packaged securely in a cardboard box.

- The box will also include foam padding to prevent any damage during transportation.

- Product dimensions: [insert dimensions here].

Shipping:

- Shipping will be handled by our trusted courier partners.

- Delivery times may vary depending on your location.

- Once the product has been shipped, you will receive a tracking number to monitor the progress of your delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!