Product Description:

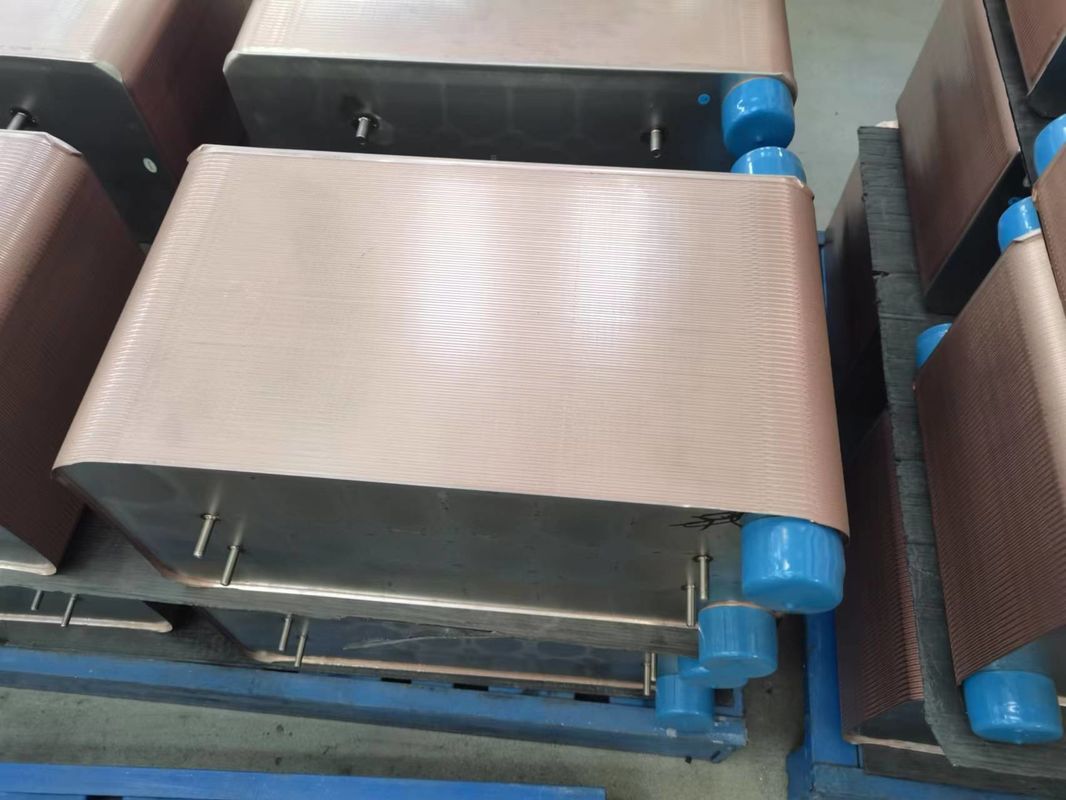

Brazed Plate Heat Exchanger

The Brazed Plate Heat Exchanger is a highly efficient and compact heat transfer device designed for a wide range of industrial and commercial applications. This product is specifically designed to provide efficient heat transfer solutions for heating, cooling, and evaporation processes.

Max Pressure: 4.5Mpa

The Brazed Plate Heat Exchanger is designed to withstand high pressures up to 4.5Mpa, making it suitable for use in a variety of industrial and commercial settings.

Heat Transfer Area: 0.03-1.2 M²

The heat transfer area of the Brazed Plate Heat Exchanger ranges from 0.03 to 1.2 M², making it a versatile and adaptable option for various heat transfer requirements.

Certifications: ISO

The Brazed Plate Heat Exchanger is certified by the International Organization for Standardization (ISO), ensuring that it meets the highest quality and safety standards.

Design Temperature: -196 To 225 C

This product is designed to operate in a wide temperature range from -196 to 225 degrees Celsius, making it suitable for use in both low and high-temperature applications.

Braze Material: Copper, Stainless Steel

The Brazed Plate Heat Exchanger is made of high-quality materials, including copper and stainless steel, which are known for their excellent thermal conductivity and corrosion resistance. This ensures the durability and efficiency of the product.

Copper Brazed Plate Heat Exchanger

The Brazed Plate Heat Exchanger is specifically designed with copper brazing, which ensures a strong and reliable bond between the plates, making it suitable for use in high-pressure and high-temperature applications.

Evaporator Plate Heat Exchanger

The Brazed Plate Heat Exchanger can also function as an efficient evaporator, making it a versatile and cost-effective option for various heating and cooling processes.

Copper Brazed Plate Heat Exchanger Price

With its compact design, high efficiency, and durability, the Brazed Plate Heat Exchanger offers a cost-effective solution for heat transfer applications. Its competitive pricing makes it an attractive option for businesses looking for efficient and affordable heat transfer solutions.

Features:

- Product Name: Brazed Plate Heat Exchanger

- Specification: Customized

- Braze Material: Copper, Stainless Steel

- Plate Design: Chevron

- Max Pressure: 4.5Mpa

- Warranty: 1 Years

- Evaporator Plate Heat Exchanger

- Fusion Bonded Plate Heat Exchanger

- Copper Brazed Plate Heat Exchanger

Technical Parameters:

| Brazed Plate Heat Exchanger |

Fusion Bonded Plate Heat Exchanger |

| Max Pressure |

4.5Mpa |

| Braze Material |

Copper, Stainless Steel |

| Certifications |

ISO |

| Connections |

Male Thread, Thread, SAE Flange, Soldering |

| Warranty |

1 Years |

| Specification |

Customized |

| Plate Design |

Chevron |

| Heat Transfer Area |

0.03-1.2 M² |

| Flow Rate |

8-300 M³/h |

| Design Temperature |

-196 To 225 C |

Applications:

Brazed Plate Heat Exchanger - Tenkai

Tenkai is a leading manufacturer of Brazed Plate Heat Exchangers in China. Our products are known for their high quality, durability and efficiency. Our Brazed Plate Heat Exchangers are designed to meet the demands of various industries and applications.

Brand Name: Tenkai

Tenkai is a trusted brand in the heat exchanger industry. Our Brazed Plate Heat Exchangers are made with the finest materials and advanced technology to provide superior performance and reliability.

Place of Origin: China

All our Brazed Plate Heat Exchangers are manufactured in our state-of-the-art facility in China. We adhere to strict quality control measures to ensure that our products meet international standards.

Design Temperature: -196 To 225 C

Our Brazed Plate Heat Exchangers are designed to operate in extreme temperatures ranging from -196 to 225 degrees Celsius. This makes them suitable for a variety of applications in different industries.

Braze Material: Copper,Stainless Steel

Our Brazed Plate Heat Exchangers are made with high-quality materials such as copper and stainless steel. These materials offer excellent thermal conductivity, corrosion resistance, and durability.

Connections: Male Thread ,Thread ,SAE Flange , Soldering

Tenkai Brazed Plate Heat Exchangers come with various connection options including male thread, thread, SAE flange, and soldering. This provides flexibility in installation and use for different applications.

Plate Design: Chevron

The plates in our Brazed Plate Heat Exchangers are designed in a chevron pattern. This design maximizes heat transfer and enhances the overall efficiency of the heat exchanger.

Certifications: ISO

Tenkai Brazed Plate Heat Exchangers are ISO certified, ensuring that our products meet international quality standards. This certification guarantees our customers of the reliability and performance of our products.

Full Welded Plate Heat Exchanger

Tenkai also offers a full welded plate heat exchanger option for more demanding applications. This type of heat exchanger is suitable for high-pressure and high-temperature applications.

Copper Brazed Plate Heat Exchanger

Our copper brazed plate heat exchangers are ideal for applications that require high corrosion resistance and thermal conductivity. They are also suitable for use in HVAC systems, refrigeration, and renewable energy systems.

High Temperature Resistance

Tenkai Brazed Plate Heat Exchangers are designed to withstand extreme temperatures. This makes them suitable for use in various industries, including chemical, oil and gas, and food and beverage.

Compact Design

Our Brazed Plate Heat Exchangers have a compact design, making them easy to install and maintain. They also take up less space, making them ideal for applications with limited space.

Energy Efficiency

Tenkai Brazed Plate Heat Exchangers are designed for maximum energy efficiency. The chevron plate design and high-quality materials ensure efficient heat transfer, reducing energy consumption and costs.

In conclusion, Tenkai Brazed Plate Heat Exchangers are the perfect solution for various industrial and commercial applications. With our superior quality, advanced technology, and certifications, we are the trusted choice for all your heat exchanger needs.

Customization:

Brazed Plate Heat Exchanger - Tenkai

Brand Name: Tenkai

Place of Origin: China

Heat Transfer Area: 0.03-1.2 M²

Design Temperature: -196 To 225 C

Plate Design: Chevron

Certifications: ISO

Braze Material: Copper, Stainless Steel

Customized Services

At Tenkai, we understand the importance of meeting our customers' specific needs. That's why we offer customized services for our Brazed Plate Heat Exchanger, including:

- Evaporator Plate Heat Exchanger design to suit your specific application

- Brazed Plate Heat Exchanger design to maximize heat transfer efficiency

- Customized plate sizes to fit your space requirements

- Various braze materials available, including copper and stainless steel

- Design temperature range of -196 to 225 C to meet your operating conditions

- ISO certifications to ensure quality and reliability

Our experienced team will work closely with you to understand your unique requirements and provide a customized solution that meets your exact specifications. Trust Tenkai for all your Brazed Plate Heat Exchanger needs.

Packing and Shipping:

Packaging and Shipping of Brazed Plate Heat Exchanger

Our Brazed Plate Heat Exchanger is carefully packaged and shipped to ensure safe delivery to your location.

Packaging

The Brazed Plate Heat Exchanger is first placed in a sturdy, high-quality cardboard box. The box is then filled with protective materials such as foam or bubble wrap to prevent any damage during transportation. The product is also securely wrapped with plastic or paper to protect it from scratches and other external factors.

For larger orders, the heat exchanger may be packaged in wooden crates to provide additional protection. Each crate is labeled with the product name, size, and weight for easy identification.

Shipping

We offer various shipping options to meet your specific needs and budget. Our products can be shipped by air, sea, or land, depending on your location and urgency of delivery.

For international orders, we ensure that all necessary customs documents and certificates are included to facilitate smooth delivery and avoid any delays or complications at customs.

Once your order has been shipped, we will provide you with a tracking number so you can monitor the progress of your delivery.

Delivery

We strive to deliver your Brazed Plate Heat Exchanger within the agreed upon timeframe. Our team works closely with trusted shipping partners to ensure timely and secure delivery to your doorstep.

Upon delivery, please inspect the package for any signs of damage. If there are any issues, please contact us immediately so we can resolve the problem.

Thank you for choosing our Brazed Plate Heat Exchanger. We hope it will provide you with reliable and efficient heat transfer for your applications.

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is Tenkai.

- Q: Where is this product made?

- A: This product is made in China.

- Q: What type of heat exchanger is this product?

- A: This product is a brazed plate heat exchanger.

- Q: What materials are used in making this product?

- A: This product is made of high-quality stainless steel or copper .

- Q: What are the advantages of a brazed plate heat exchanger?

- A: Brazed plate heat exchangers have high heat transfer efficiency, compact size, and low maintenance requirements.

- Q: Is this product suitable for high-pressure applications?

- A: Yes, this product is designed to handle high-pressure applications with ease.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!