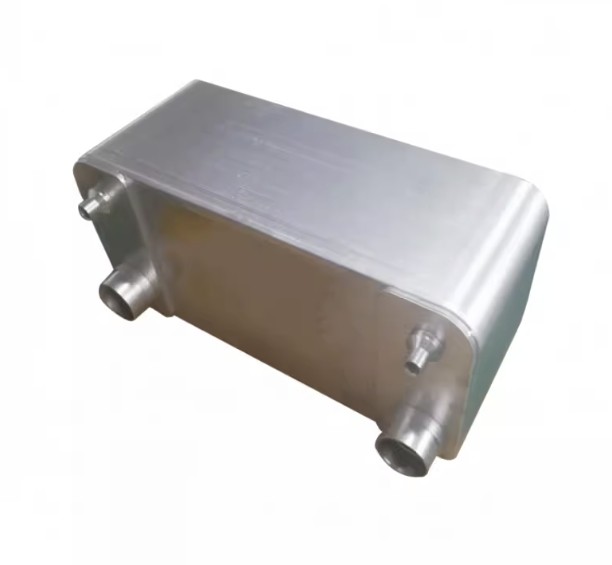

Heat Transfer Device 100% Stainless Steel Box Type Fusion Bonded Plate Heat Exchanger In Oil And Gas Industry

| TYPE |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

THICKNESS(mm) |

WEIGHT(Kg) |

MAX FLOW m3/h) |

DESIGN PRESSURE (Mpa) |

| BT350BR |

318 |

160 |

1060 |

912 |

44+2.23N |

79.3+1.31N(N<132)

82.23+1.404N(N≥132)

|

50 |

0.5 |

|

|

|

Introduction :

Box-type fusion-welded plate heat exchanger is a highly efficient heat transfer device that consists of a series of welded plates enclosed within a box-like structure. It is designed to provide optimal heat transfer performance and is commonly used in various industrial applications.

The heat transfer process in a box-type fusion-welded plate heat exchanger occurs through alternating channels formed by the welded plates. The hot and cold fluids flow through these channels, allowing for efficient heat exchange. The welding technique ensures a secure and leak-free connection between the plates, maintaining the integrity of the system.

Box Type Fusion Welded Plate Heat Exchanger , box material is Q35 , all stainless steel inside welded plate heat exchanger .

System design available for assemble for signle component , also can assemble with more box type heat exchanger .

The operating temperature 0-170 ℃ , satisfy application in special industry .

Features:

Compact design: Box-type fusion-welded plate heat exchangers have a compact and space-saving design. The welded plates are arranged in a box-like structure, allowing for a large heat transfer surface area within a small footprint. This compact design is beneficial in installations where space is limited.

High thermal efficiency: The fusion-welded plates in the heat exchanger are designed with corrugations or chevrons, which enhance the heat transfer process. These corrugations create turbulence in the fluid flow, maximizing the contact between the hot and cold fluids and improving overall thermal efficiency.

Wide material compatibility: The plates of the heat exchanger are typically made of high-quality materials such as stainless steel or titanium. These materials offer excellent corrosion resistance, making the heat exchanger compatible with a wide range of fluids, including corrosive or aggressive media.

Easy maintenance and cleaning: The modular design of box-type fusion-welded plate heat exchangers allows for easy access to the plates, simplifying maintenance, cleaning, and inspection procedures. This feature contributes to the longevity and optimal performance of the heat exchanger.

High-pressure capability: Box-type fusion-welded plate heat exchangers are designed to handle high-pressure applications. They can effectively accommodate the demands of industrial processes that require heat transfer under elevated pressures.

These features collectively make box-type fusion-welded plate heat exchangers efficient, reliable, and suitable for a wide range of industrial applications where compactness, high thermal efficiency, and durability are essential.

Test Area :

Workshop :

Package Area :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!