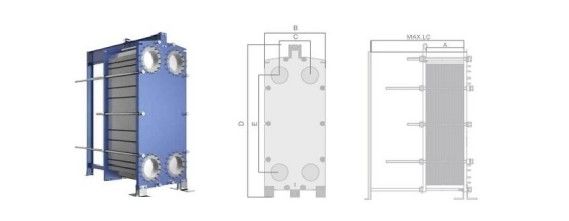

B100B Series Gasket Plate Heat Exchanger Ti,ti-pd Material For Chemical Industry

Gasketed plate heat exchangers (GPHEs) are widely used in various industries and applications where efficient heat transfer is required. Here are some common applications of gasketed plate heat exchangers:

HVAC Systems: GPHEs are extensively used in heating, ventilation, and air conditioning systems. They are employed for applications such as heat recovery, district heating, and cooling, as well as for providing hot water for domestic and commercial use.

Industrial Processes: GPHEs play a crucial role in numerous industrial processes that involve heat exchange. They are used in industries such as chemical, pharmaceutical, oil and gas, pulp and paper, and power generation. GPHEs are utilized for applications like process heating and cooling, heat recovery, condensation, evaporation, and pasteurization.

Refrigeration and Cooling: GPHEs are commonly employed in refrigeration systems, including industrial refrigeration, cold storage, and air conditioning units. They facilitate heat exchange between the refrigerant and the cooling medium, ensuring efficient cooling and temperature control.

Food and Beverage Processing: GPHEs are extensively used in the food and beverage industry for various heat transfer applications. They are employed in processes such as pasteurization, sterilization, heating, cooling, and evaporation of food and beverage products.

Power Generation: GPHEs are utilized in power plants for heat recovery and cooling applications. They help in efficient heat exchange between different fluids, such as cooling water, steam, and condensate, optimizing power plant performance and reducing energy consumption.

Marine and Offshore Applications: GPHEs find applications in marine and offshore industries, including shipbuilding, offshore oil and gas platforms, and marine power systems. They are used for various heat transfer processes, such as cooling of engines, heat recovery, and HVAC systems.

Waste Heat Recovery: GPHEs are employed in waste heat recovery systems to capture and utilize waste heat from industrial processes. They facilitate the transfer of heat from the waste stream to a usable medium, improving energy efficiency and reducing environmental impact.

District Heating and Cooling: GPHEs are utilized in district heating and cooling networks, where heat is distributed from a central source to multiple buildings or facilities. They enable efficient heat exchange between the central heating or cooling medium and the distributed network, ensuring effective temperature control.

Solar Thermal Systems: GPHEs are used in solar thermal systems to transfer heat from solar collectors to the working fluid. They enhance the efficiency of solar heating systems by facilitating efficient heat exchange between the solar energy source and the heat transfer medium.

| TYPE |

A(mm) |

B(mm |

C(mm |

D(mm) |

E(mm) |

Height ( mm ) ( from middle of bottom to ground )(mm) |

MAX,LC

(mm)

|

Connector Path (mm) |

Max Flow (m3/h) |

Design Pressure (Mpa) |

Max Pieces |

| B30B |

N(2.5+X) |

180 |

60 |

480 |

357 |

62 |

500 |

32 |

18 |

1.0 |

95 |

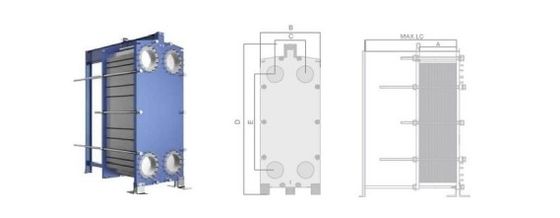

| B60B |

N2.0+X |

320 |

140 |

920 |

640 |

140 |

1200 |

50 |

36 |

1.6 |

250 |

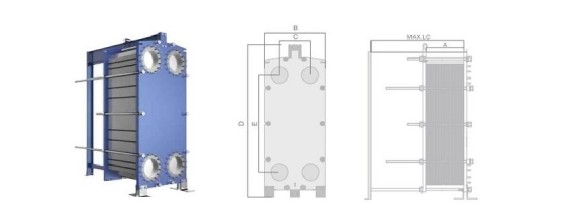

| B60H |

N(3.0+X) |

320 |

140 |

920 |

640 |

140 |

1200 |

50 |

36 |

1.6 |

203 |

| B100B |

N(2.55+X) |

470 |

225 |

1069 |

719 |

183 |

1600 |

100 |

140 |

1.0/1.6/2.5 |

278 |

| B100H |

N(3.95+X) |

470 |

225 |

1069 |

719 |

200 |

1600 |

100 |

140 |

1.0/1.6/2.5 |

180 |

| B150B |

N(2.5+X) |

610 |

298 |

1815 |

1294 |

275 |

3000 |

150 |

360 |

1.0/1.6/2.5 |

600 |

| B150H |

N(3.95+X) |

610 |

298 |

1815 |

1294 |

275 |

3000 |

150 |

360 |

1.0/1.6/2.5 |

600 |

| B200H |

N(4+X) |

780 |

353 |

2260 |

1478 |

380 |

3000 |

200 |

600 |

1.0/1.6 |

480 |

| B250B |

N(2.5+X) |

920 |

439 |

2895 |

1939 |

435 |

3000 |

250 |

750 |

1.0/1.6/2.5 |

500 |

| B350B |

N(3.3+X) |

1150 |

596 |

2882 |

1842 |

470 |

4800 |

350 |

997 |

1.0/1.6 |

700 |

Loading :

Package :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!